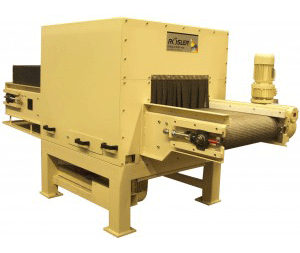

Rotary Barrel / Belt Air-Dryer

After the finishing process wet parts must be dried. One method is to use a rotary drum filled with absorbent material such as ground corn cob or wood chips. The parts are gently dried in the heated drying medium and then separated and emptied from the drum. Another method is to use a conveyor belt and high velocity air to blow off the water from the parts. Both methods are meant for high volume of parts that need to be dried.

We distribute Electric heated belt and rotary barrel Dyrers manufactured by :

1. Walther Troval

2. Royson Engineering

3. Rosler Metal Finishing

2. Royson Engineering

3. Rosler Metal Finishing

4. C.L.M VibTech